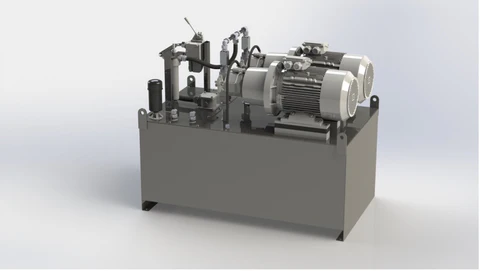

Hydraulic power packs are essential components in many manufacturing facilities. They provide the hydraulic power necessary to operate machinery and equipment. However, hydraulic power packs can be dangerous if they are not operated properly. By following safety procedures and being alert, operators can avoid accidents and injuries when working with hydraulic power packs.

Inspect the Equipment

Before starting up a hydraulic power pack, conduct a thorough inspection. Check fluid levels in the reservoir to ensure there is adequate hydraulic fluid. Inspect the hoses and fittings for wear, cracks, leaks, or other damage. Make sure all guards and shields are in place. Look for loose bolts, damaged parts, and other issues that require maintenance. Do not operate any hydraulic power pack that is not in proper working condition.

Understand the System

Read all manuals and become completely familiar with the hydraulic system prior to operating it. Know the operating pressures and flow rates. Locate all valves and controls. Understand how each component functions and learn the proper startup and shutdown procedures. An experienced supervisor should provide training and approval before allowing anyone to operate hydraulic equipment. Any hydraulic power pack and hydraulic power packs should be sourced from reputable suppliers too.

Wear Protective Equipment

Use appropriate personal protective equipment when working around hydraulic power packs. At a minimum, this includes eye protection, sturdy footwear, long pants, and tight sleeves. Additional items like hard hats, hearing protection, and gloves may be necessary. Remove all jewellery and restrain any loose clothing that could get caught in moving parts.

Follow Safety Procedures

Always follow the proper procedures outlined in the equipment manuals. Do not take shortcuts or bypass any safety mechanisms. Use both hands when operating controls to maintain stability. Proceed slowly and double check all valves and controls before starting up a hydraulic system. Monitor pressure gauges and listen for unusual sounds. Shut it down immediately if there are any indications of a problem.

Keep the Area Clear

Ensure the area around the hydraulic equipment is clean, dry, and free of debris before startup. All personnel should be kept at a safe distance from the hydraulic power pack while it is operating. Never disable or override guards, shields, or barriers. Make sure nothing can get lodged in moving parts. Store materials, tools, and other objects away from walkways and work areas.

Conduct Regular Maintenance

Do routine checks and follow the manufacturer’s maintenance schedule. Tighten any loose bolts and fittings. Replace any damaged hoses. Drain and replace the hydraulic fluid periodically. Make sure the filters are clean. Identify any signs of wear on system components. Address minor issues promptly to prevent major problems down the line. Record all maintenance activities for future reference.

Hydraulic power packs enable many manufacturing processes. By adopting safe work practices, operators can harness hydraulic power efficiently while avoiding serious injuries. Be properly trained, wear protective gear, follow procedures, and maintain the equipment in good working order at all times. Making safety the top priority will help maximise productivity while keeping personnel safe.

Keep an eye for more latest news & updates on ZOLTRAKK!